The Cresco Calibration Centre

Precision Perfected

How It Works:

The calibration machine replicates a real-life spreading experience by maintaining a consistent walking speed of 3 mph, ensuring reliable test conditions.

The spreader releases fertilizer onto a testing surface where the pattern is captured and analyzed for even distribution.

By rigorously testing different fertilizers, we generate a comprehensive calibration guide, providing pre-tested settings for various products, so you can spread with confidence.

With Cresco’s pre-calibrated settings, you no longer need to rely on trial and error—just set your spreader, follow our guidance, and achieve uniform coverage every time.

Slide System Technology: Adaptable & Efficient

- Even distribution across different fertilizers and seeds.

- Customizable settings for precision spreading.

- Multi-season use, enabling the same spreader to switch seamlessly between fertilizer and salt application.

Whether you’re a professional groundskeeper or a home gardener, Cresco’s technology ensures effortless, precise, and efficient spreading, no matter the season.

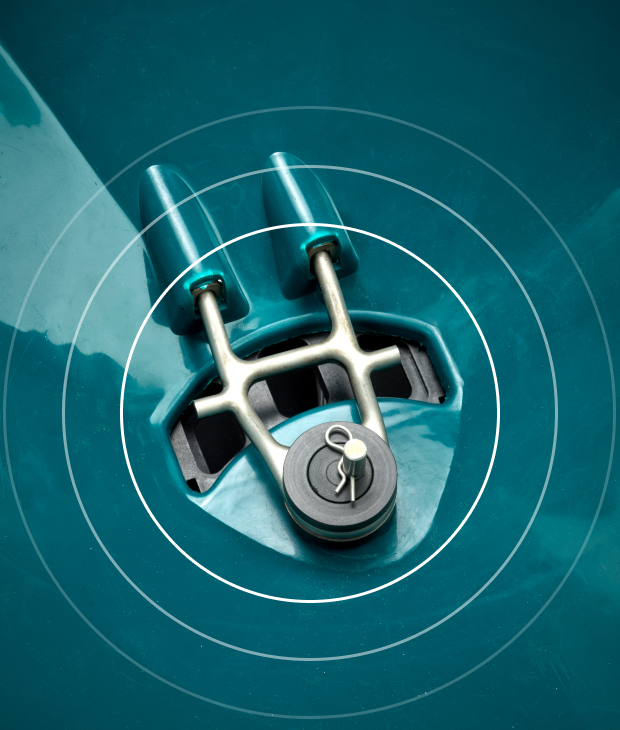

The Spider Agitator

Smooth & Consistent Flow

Clumping and blockages can disrupt spreading efficiency, leading to uneven distribution. That’s where Cresco’s Spider Agitator comes in.

Why It Matters:

Keeps fertilizers, grass seeds, and salt flowing smoothly through the spreader.

Avoids sudden bursts or uneven application, improving spreading accuracy.

Built to handle different materials without excessive wear.

By continuously rotating inside the hopper, the Spider Agitator ensures that materials stay loose and flow consistently, eliminating frustration and wasted product.

Why Choose Cresco Technology?

Scientifically tested for unmatched accuracy

Eliminates manual calibration errors

Saves time and reduces product waste

Designed for versatility and ease of use

Experience the next level of spreading precision with Cresco Spreaders.